MIXED SIGNAL

IS OUR STRENGTH

HMT specialises in “mixed signal” ASICs, modules and microelectronic systems, particularly for sensors and actuators. In these devices the analogue elements meet the digital directly, in tough and varied environments such as industrial, aeronautic, automotive and medical.

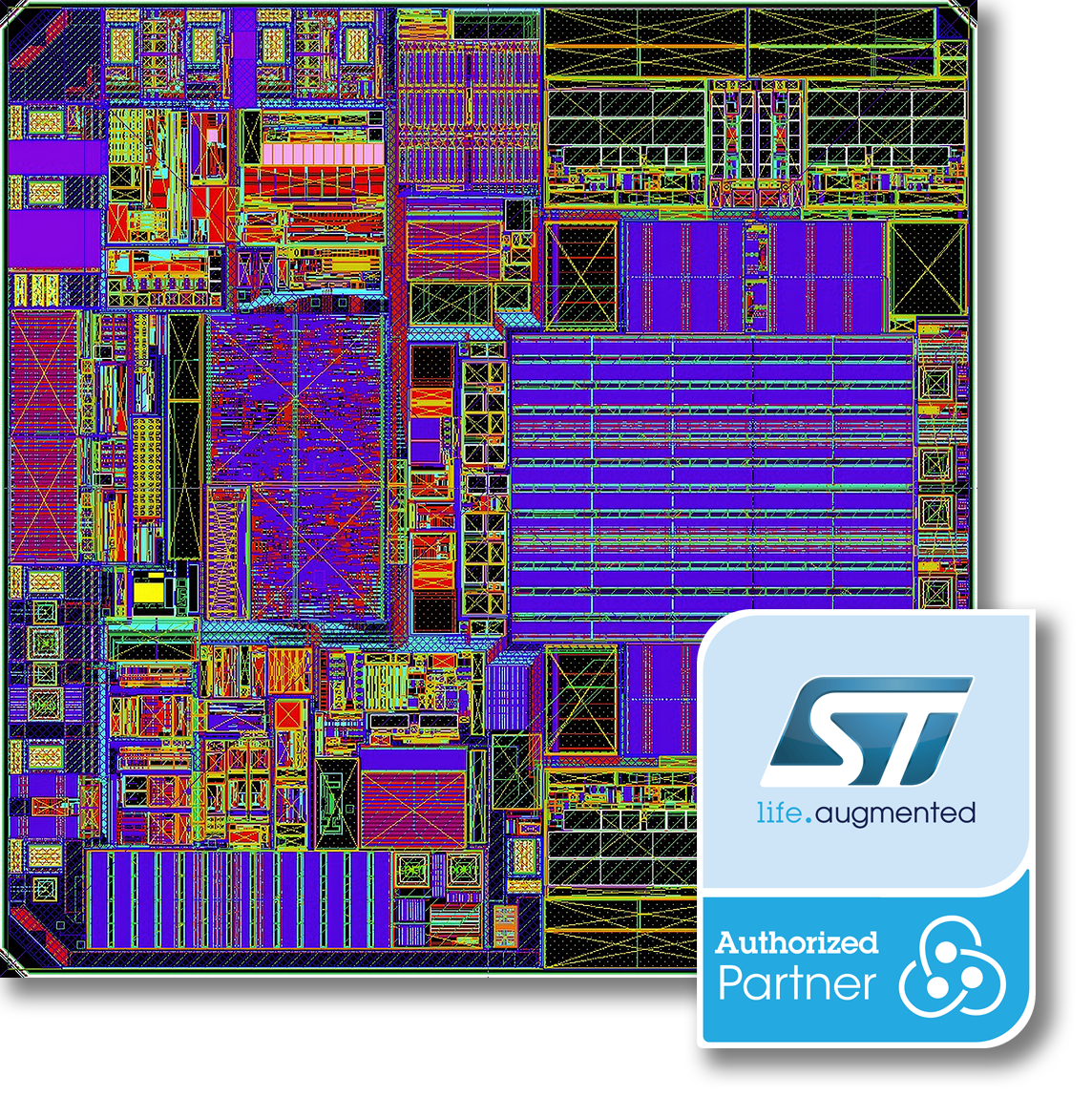

About Robust ASICs

Robust ASICs handle high on-chip voltages and currents and are built to survive EMC events. The devices are built with semiconductor technologies demonstrated to have stable production and long operating life, which have additional been qualified and certified to prove it. HMT works with foundry partners who provide high-voltage technologies (BCD, up to 800V) and automotive qualification.

- high-voltage processes from automotive qualified foundries (piezo to 250V)

- silicon on insulator processes and design techniques optimised for these processes

- high temperature operation (>200°C)

- direct connection of power with integrated industrial surge protections (IPs)

- isolated communication techniques to high-voltage islands (Level Shifing IPs)

- physical thermal and electrical finite element modelling

- production test at multiple temperatures

- production test with high-voltage test equipment

Automotive ASICs

- automotive qualified foundry and assembler partners with long term process availability

- test orientated ASIC design and production flow for zero defect strategies, aligned with partner foundries

- AEC-Q100 test design, conduction and evaluation for qualification – PPAP

- in house production test at multiple temperatures with statistical processing techniques (PAT , cluster, etc.) for zero defect testing

- on-site and local partner based failure analysis for accurate failure investigation in design, qualification and from the field.

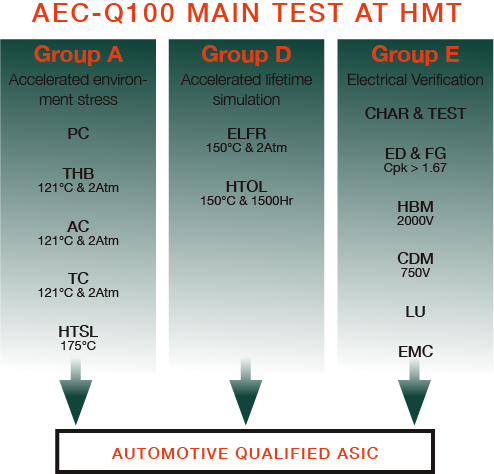

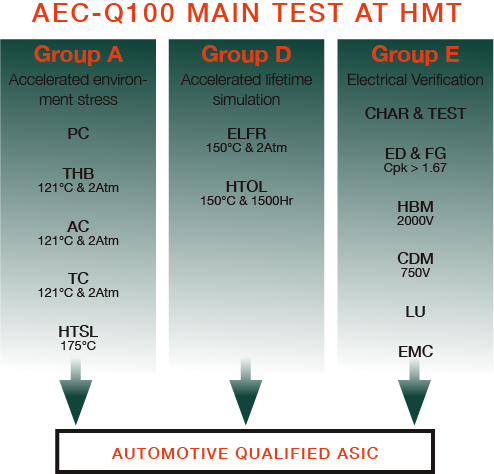

Qualification AEC-Q100

HMT runs a full AEC-Q100 qualification flow to grade 0 (-40°C to 150°C application ambient), MSL (Moisture Sensitivity Level) 3. The test conditions are defined in a QTP (Qualification Test Plan according to the Automotive Electronics Council) with the customer based on the application. Sections of the qualification are provided by our automotive qualified foundries and assemblers, where as appropriate.

HMT also works together with automotive certified partners to assure the complete test coverage.

HMT ASICs typically operate with significant voltages or currents or have a high temperature stress. HMT provides the design of appropriate HTOL (High Temperature Operating Life) and ELFR (Early Life Failure Rate) testing to cover the device electrical and thermal mission profile defined by the customer for the application.

These challenging tests are carried out at the HMT facility, where the parts are submitted to an exhaustive control (pre, post and interim electrical tests), in order to monitor their correct performance during this section of the qualification phase.

HMT takes care of all the burn-in hardware and equipment required to carry out the elevated temperature tests.

Motor Driver ASICs

- isolated communication techniques using floating islands (level-shifting of digital and analogue signals) (IPs)

- high-voltage isolated element power supply and biasing techniques (IPs)

- combined sensor and power electronics in one integration for sensorless motors

- high temperature qualified packages (to 150°C, automotive grade 0)

- energy recovery and regeneration techniques (IPs for piezo and MEMS)

- regulators (linear, DC-DC, charge-pump) trimmed for specific applications

- on-chip sensor front-ends and direct coil back-EMF measurement

Actuator ASICs & Power Conversion

Piezos and solenoids are ubiquitous in industry: from airflow control to electrical protection, they reliably and efficiently bridge between the electronic and mechanical worlds. Custom ASICs offer clear advantages for equipment manufacturers:

- cost reduction – by cutting the bill of material for the power supply, analogue front-end and electronic interface

- size – integration gives access to minimum dimensions; custom device pin-out and standard chip scale packaging fit the tightest spaces

- parallelism – many channels can be controlled in a cost-effective manner saving on cabling and assembly

- efficiency – with more accurate current and voltage control, and dc-dc converter techniques, lower power can be used for the actuation allowing higher packing densities or higher operating frequencies

- diagnostics – access to the analogue components, and free digital gates enable self-monitoring, giving early warning of device ageing and facilitating maintenance

HMT microelectronic AG

Alfred-Aebi-Strasse 75

2503 Biel/Bienne – Switzerland

+41 (0) 32 365 11 81

mailbox@hmt.ch

www.hmt.ch