THE CORNERSTONE

OF OUR SUCCESS

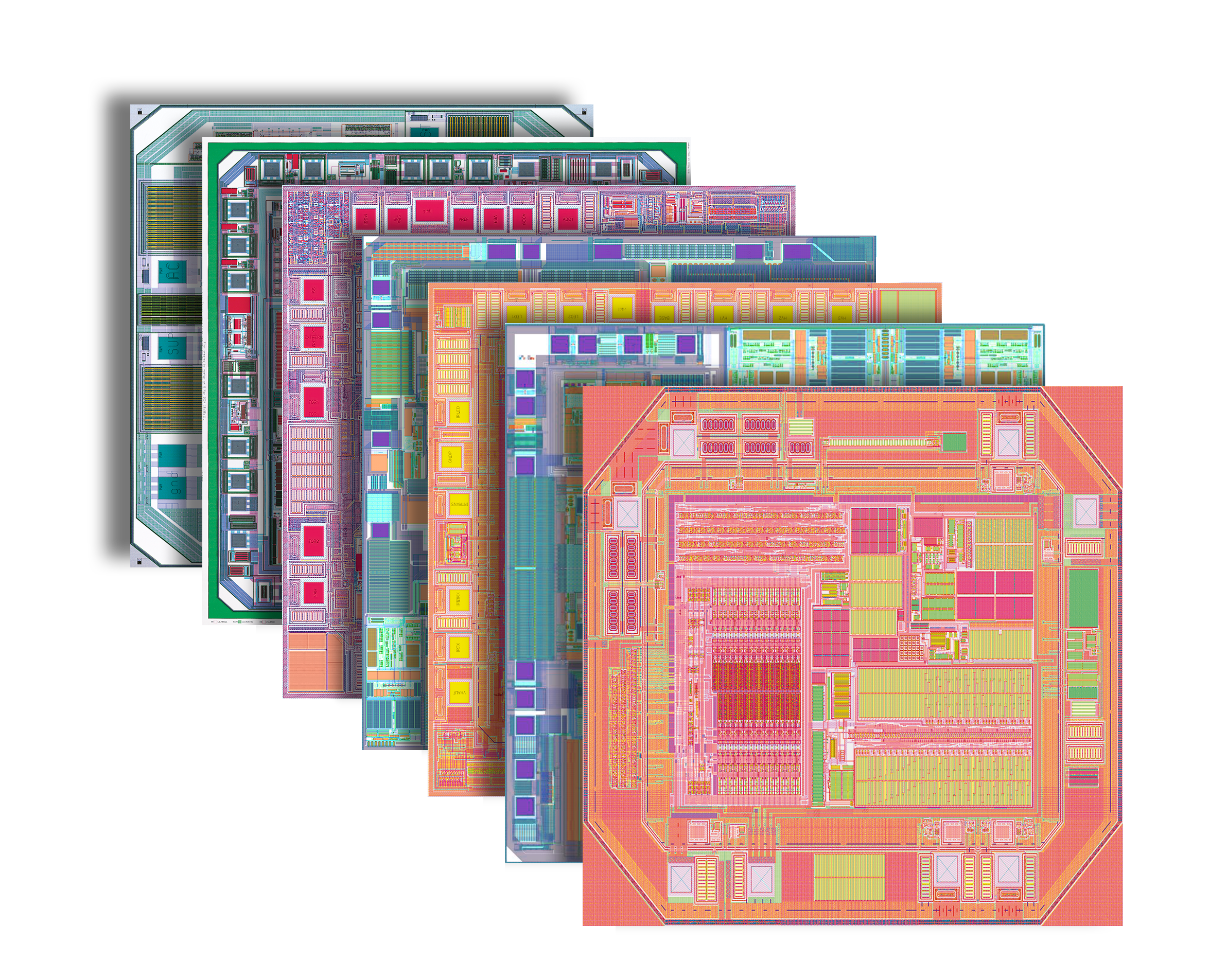

HMT works together with key European and US foundry partners with automotive qualified technologies, long-term technology availability guarantees and quality assurance agreements. Continue reading below…

1. Foundry Partners

HMT works together with key european and US foundry partners with automotive qualified technologies, long-term technology availability guarantees and quality assurance agreements.

For our demanding products, a close cooperation with foundries is essential. We work together as official foundry design partners or in sub-contract to the foundries to promote a close working relationchip and to enusre optimum technology access.

ASICs generally form a critical element of a customer’s product and security stock agreements are available.

As volumes of a product grow, second sourcing and a lean supply chain is important. HMT provides flexible business models together with our foundries to allow transfer of assembly and test to foundry for higher volume or for delivery security. This is carried out while retaining responsibility for product qualtiy with HMT and all products are statistically monitored at HMT to ensure design and production test stability.

There are medical and aeronautic products produced in high volumes, but typically the volumes are moderate. As a foundry customer, HMT can provide the support for these volumes for ASIC manufacture and test.

1.1 ST Microelectronics

HMT microelectronic AG has been working with STMicroelectronics for 25 years. Using state of the art ST technologies, HMT has designed more than 50 ASICs with STMicroelectronics, mainly for sensors and motor drives with manufacturing volumes in excess of 10 Mio. HMT is developing more than 5 further ASICs with ST in 2016 alone, and this trend is expected to continue.

“The ST BCD (Bipolar CMOS DMOS) family provides an ideal base for high performance mixed signal ASICs where medium voltage (<190V) high power elements are efficiently integrated with precision analog sensor circuits and dense logic. The range of process options provides flexibility, tailoring the technology capability to the needs of individual customer products,” said HMT CEO Andreas Reber, explaining the reason for their technology choice.

One BCD family option of particular and growing interest to Industrial Customers is SOI (Silicon on Insulator). HMT microelectronic AG has special know-how exploiting the advantages of SOI, further improving the integration density of medium voltage circuits and providing high performance and well isolated functions on a single silicon (SoC).

1.2 ON Semiconductor

HMT microelectronic AG develops with a range of medium and high voltage ON technologies in the 0.35µm to 0.7µm range. These provide switching devices to 80V, a full array of analog devices and digital libraries, full automotive qualification, radiation hard cells and are suitable for mixed low noise/medium voltage designs.

Deep trench isolation in the bulk process allows good isolation of circuit elements and efficient device geometries.

1.3 EM MICROELECTRONIC

EM Microelectronic is a semiconductor manufacturer specialized in the design and production of ultra low power, low voltage integrated circuits for battery-operated and field-powered applications in consumer, automotive and industrial areas. Their technologies are targeted to low power RFID circuits, smart cards ICs, ultra-low power microcontrollers, power management, LCD drivers and displays, sensor and opto-electronic ICs

HMT has developed a number of medical products, communications products and remotely powered products with EM MICROELECTRONIC.

1.4 Microchip Technology Inc.

Microchip is a worldwide leader in the design and manufacture of microcontrollers, advanced logic, mixed-signal, non-volatile memory and radio frequency (RF) components. Microchip is able to provide the electronics industry with complete systems solutions focused on consumer, industrial, security, communications, computing and automotive markets.

HMT has multiple designs in the 0.7um Silicon On Insulator technology providing a robust option for power designs, with a full range of analog devices.

1.5 Assembly partners

We provide options for the assembly of ASICs:

• plastic packaging (QFN, TQFP and SOP)

• flip-chip packaging

• raw dice

HMT sources IC packaging services from multuple assemblers (packagers) for grade 0 automotive qualified packages to provide a stable multiple source supply channels.

Plastic packaging is available in a range of standard sizes as well as custom packages. Custom packages are especially helpful where an ASIC must be long and thin, which is common for sensor and medical housings.

Chip-scale packaging places solder balls onto the pads of the ICs in a wafer-scale process which provides a “packaged” device which is the same size as the silicon. An additional redistribution layer can be added to give additional freedom to the placement of the solder balls.

Stud bump placement using a wird bonder provides additional flexibility for low numbers of bumps per wafer, or the use of externally sourced wafers which are unsuitable for post-procedding.

2. Microelectronic manufacturing service partners

2.1 Hybrid SA

Hybrid SA based in Neuchâtel, Switzerland, provides in-group micro-electronic manufacturing services including production and test of miniature modules with medical certification. Hybrid SA provides all forms of miniature electronic assembly on a wide range of substrates.

2.1 Grossenbacher SA

Grossenbacher SA. St. Gallen, provide medically certified electronic assembly services including production and test.

HMT microelectronic AG

Alfred-Aebi-Strasse 75

2503 Biel/Bienne – Switzerland

+41 (0) 32 365 11 81

mailbox@hmt.ch

www.hmt.ch