LOW NOISE DESIGN

WE KNOW HOW

We know all about low-noise design. To make the best use of the signal, we require designs using suitable semiconductor devices and techniques optimised to minimise the electrical noise added by the circuit. This is particularly relevant for capacitive, inductive, optical, and temperature sensors and in radio receivers.

ASICs for Sensing

Sensors bridge from the physical world to electronics, for which they require specialised analogue electronics both for excitation and signal evaluation. Here custom integrations offer key advantages:

- Low noise design for sensor electronics to extract the most from the physics, capacitive, inductive, optical, temperature sensing.

- ADCs optimised for the application to maximise performance (resolution or speed), minimise size, power consumption

- low-power/low-voltage techniques to stretch battery life, for two wire applications and to limit self-heating

- maximum integration for minimum size and cost, narrow IC dice and custom packages

- high-voltage stimulation of sensors

- high-voltage back-end line drivers with integrated protections on chip

- non-volatile memory for on-chip calibration and configuration through power cable

ASICs for MEMS

- Low noise design to extract the most from the physics.

- on-chip charge pump techniques including regeneration to generate MEMS stimulus voltages from low (eg. battery) supplies

- high-voltage stimulation of sensors

- ADC’s with capacitive sensor front-ends, piezo sensor front-ends

- low-noise charge amplifier design for primary function and local feed-back

- high-voltage low power techniques, including power recovery for piezo sensing and actuation

- Electronics delivered as dice for system in package assembly and as CSP (solder-balls)

- dice can be stud-bumped for flip-chip assembly (option for moderate volume and prototyping).

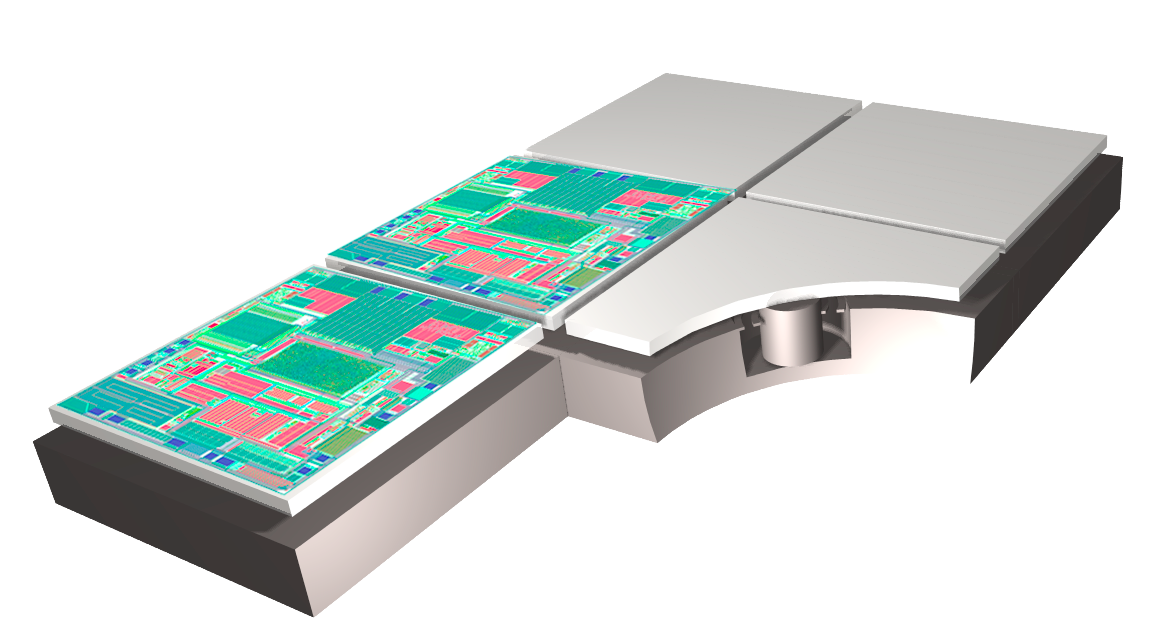

Medical ASICs

- design for micro-power operation with battery or remote power

- the highest packaging density and flexible material selection.

- technologies for near field communication

- cross discipline designs with foundry partners with technologies for mixed-signal low-power ICs over long technology life-time.

- business models allow for moderate volume production of ICs

- design traceability assured for product certification

- ISO13485 qualified for the supply of medical devices (design processes and verification, manufacturing processes, supplier management, part traceability.)

ASICs for Avionics

- radiation hard design techniques and foundry processes with design kit data

- AEC-Q100 qualification

- design traceability assured for product certification, compatible with DO-254

- non-volatile memory with serialisation in production provides individual part tracing

- mixed signal and system level simulations demonstrate that applications will function correctly at a high level of abstraction

- full digital design based on customer requirements

- incorporation of customer digital with back-end integration (place and route, scan-path and ATPG insertion) at HMT

Actuator ASICs & Power Conversion

Piezos and solenoids are ubiquitous in industry: from airflow control to electrical protection, they reliably and efficiently bridge between the electronic and mechanical worlds. Custom ASICs offer clear advantages for equipment manufacturers:

- cost reduction – by cutting the bill of material for the power supply, analogue front-end and electronic interface

- size – integration gives access to minimum dimensions; custom device pin-out and standard chip scale packaging fit the tightest spaces

- parallelism – many channels can be controlled in a cost-effective manner saving on cabling and assembly

- efficiency – with more accurate current and voltage control, and dc-dc converter techniques, lower power can be used for the actuation allowing higher packing densities or higher operating frequencies

- diagnostics – access to the analogue components, and free digital gates enable self-monitoring, giving early warning of device ageing and facilitating maintenance

HMT microelectronic AG

Alfred-Aebi-Strasse 75

2503 Biel/Bienne – Switzerland

+41 (0) 32 365 11 81

mailbox@hmt.ch

www.hmt.ch